Dynamometer Design & Manufacture

Dyna Pro Dynamometers Ltd enjoys the latest high-tech premises and employs a highly trained, highly skilled workforce

specializing in precision sheet metal work, CNC punching, Laser cutting, Folding, Welding, Electronic and Software design and

development. The very latest CNC equipment has ensured that Dyna Pro's quality remains unbeatable.

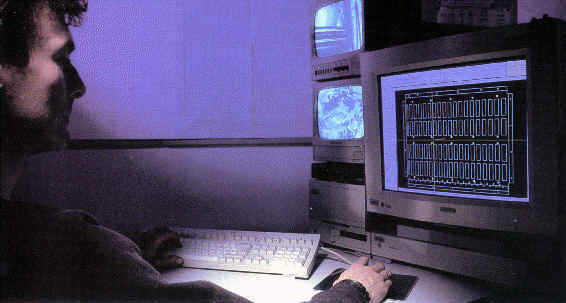

All our CNC machinery is programmed 'off-line' by fully integrated CAD\CAM systems.

The latest Radan Computational CAD\CAM software with the ability to create 2D and 3D solid

modeling.

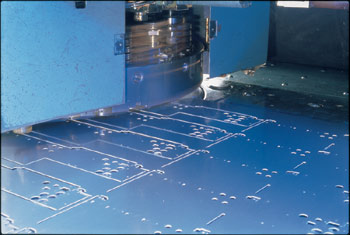

The very latest CNC laser technology can cut through virtually any material,

Laser Cutting can hold an accuracy down to 50 microns (material dependent).

Cost effectiveness and high speed performance, make the CNC Punch Press, excellent for Dyno production runs.

CNC control ensures high accuracy and repeatability throughout the complete batch.

Dyna Pro Dynamometers Ltd uses the latest CNC controlled 'Press Brakes'.

Key advantages include the formation of complex shapes to a high degree of accuracy.

Programs can be down loaded and locked into memory for future production runs

Continuing on the quality theme...........

The welding process is crucial, with various types of welding processes used throughout the manufacture

of all our Dynamometers.

Dyna Pro Dynamometers Ltd offers a quality driven service, geared to our customers very specific requirements.

100% and staged inspection is implemented throughout the entire manufacturing process with an extensive range of

inspection equipment.

Our commitment to quality and to our customers satisfaction is

paramount.

If you require any help or assistance then please call or email us.

sales@dynapro.co.uk

|